FANUC数控铣床编程实例11-轮廓铣削铣削整圆-圆形腔

FANUC数控铣床编程实例11-轮廓铣削铣削整圆-圆形腔

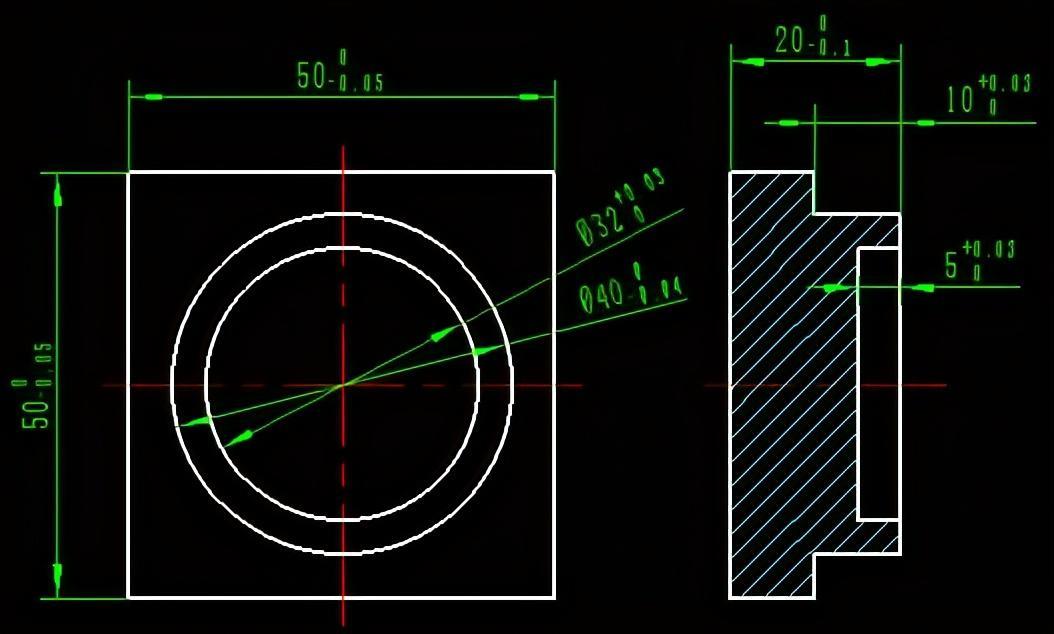

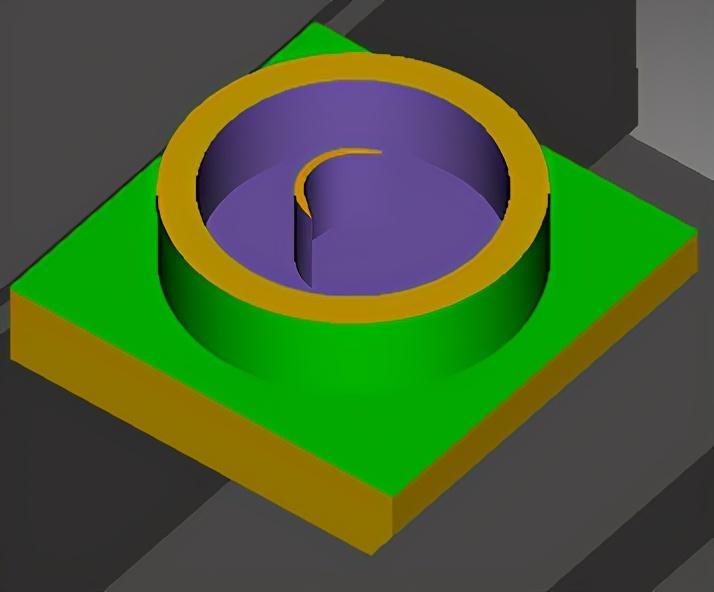

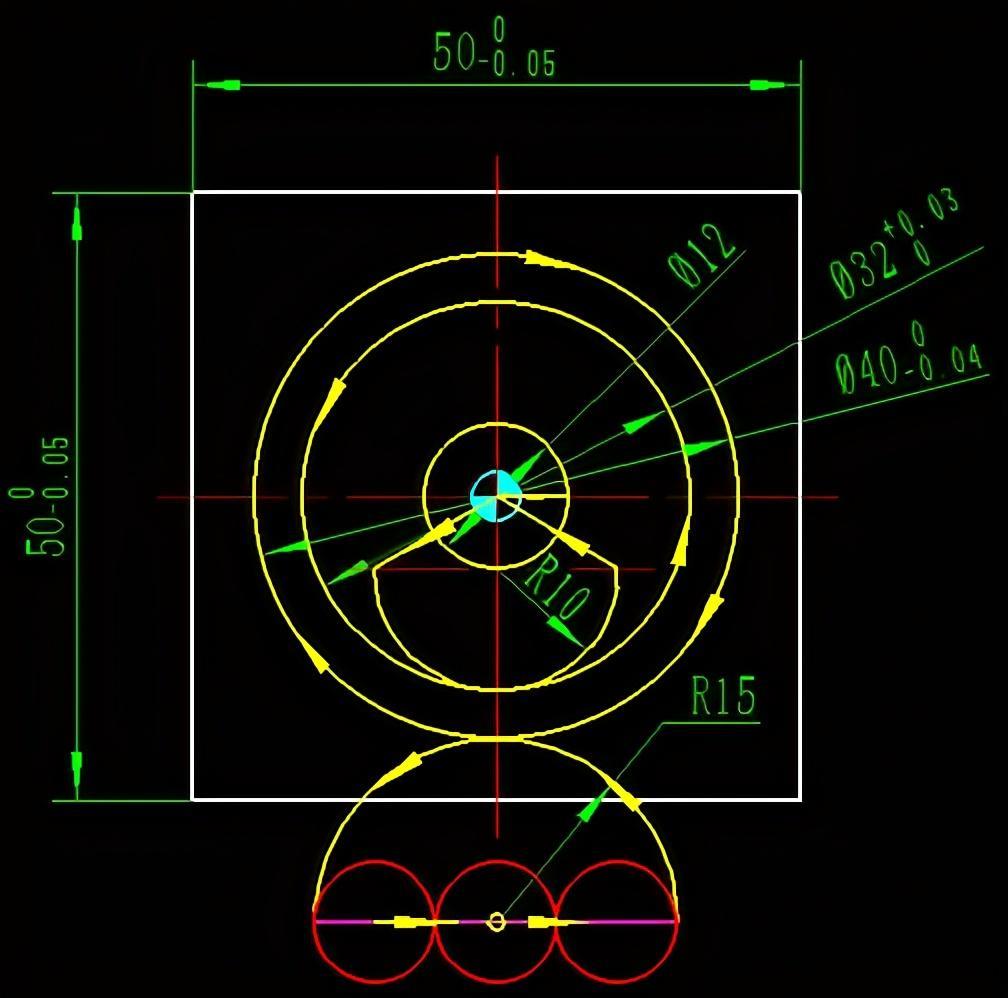

加工下面零件的圆形凸台和圆形腔。

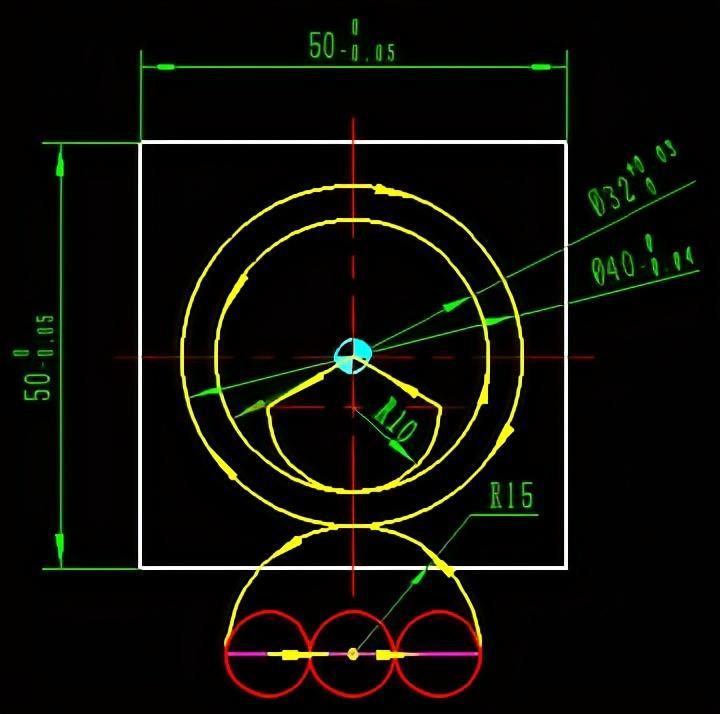

刀具轨迹安排如下

先加工外轮廓,使用直径10mm立铣刀,D01=5,D02=13,参考程序如下

T01M6

G90G54G40G43H1G00Z100M03S2500

M08

G00X0Y-35

G00Z5

#1=-2

N10 G1Z#1F500

G1G41X15D02

G3X0Y-20R15

G2X0Y-20I0J20

G3X-15Y-35R15

G1G40X0

#1=#1-2

IF [#1GE-10] GOTO 10

#1=-2

N20 G1Z#1F500

G1G41X15D01

G3X0Y-20R15

G2X0Y-20I0J20

G3X-15Y-35R15

G1G40X0

#1=#1-2

IF [#1GE-10] GOTO 20

G0Z100

T0M6

M9

M5

M30

圆形腔的加工程序,在原点垂直下刀,圆弧切入切出。

T01M6

G90G54G40G43H1G00Z100M03S2500

M08

G00X0Y0

G00Z5

#1=-2

N20 G1Z#1F20

G1G41X-10Y-6D01F300

G3X0Y-16R10

G3J16

G3X10Y-6R10

G1G40X0Y0

#1=#1-2

IF [#1GE-10] GOTO 20

G0Z100

T0M6

M9

M5

M30

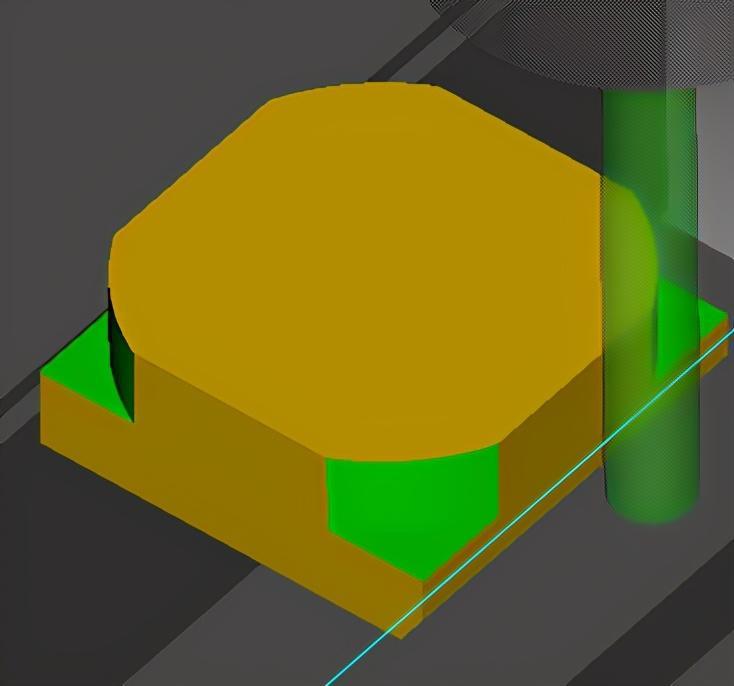

由仿真结果看出,只加刀补,切削一圈会有残余余料不能完全切出,需要再加上一圈走刀轨迹。

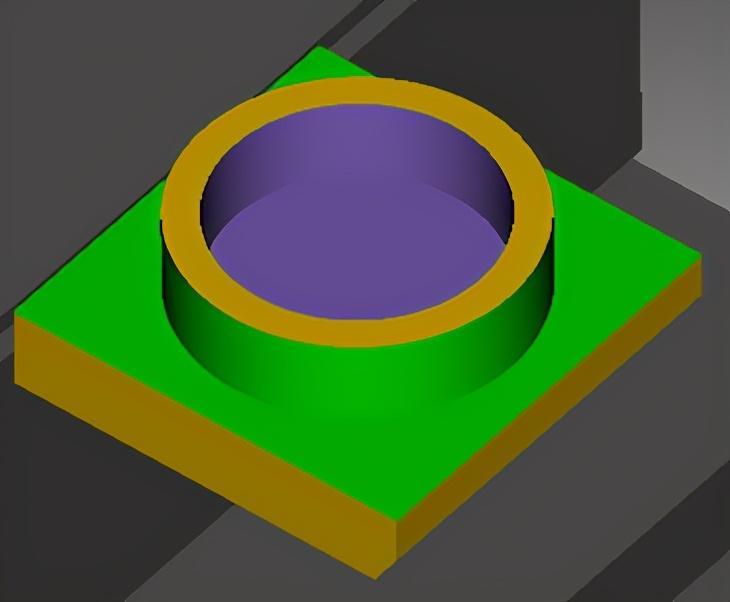

参考程序

T01M6

G90G54G40G43H1G00Z100M03S2500

M08

G00X0Y0

G00Z5

#1=-2

N20 G1Z#1F20

G1X6F300

G3I-6

G1X0

G1G41X-10Y-6D01F300

G3X0Y-16R10

G3J16

G3X10Y-6R10

G1G40X0Y0

#1=#1-2

IF [#1GE-10] GOTO 20

G0Z100

T0M6

M9

M5

M30

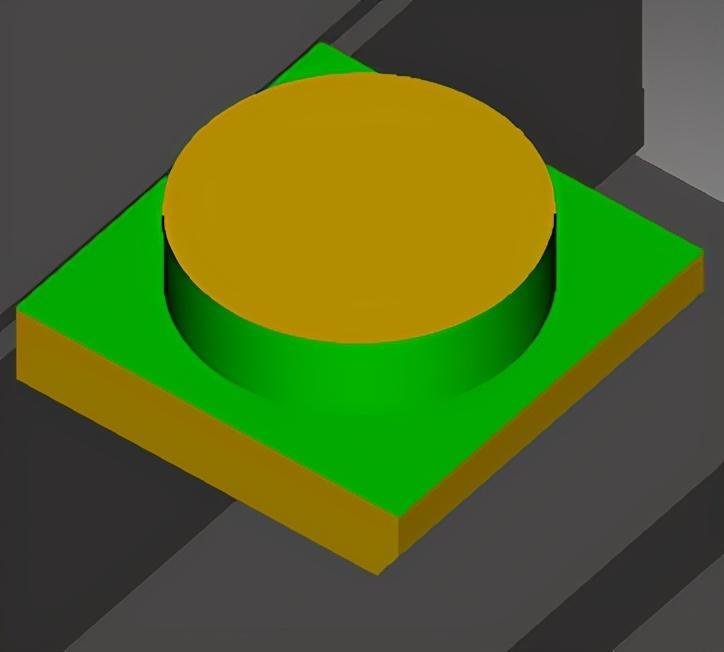

仿真结果

-

- 世界仅有的藏獒之鬼獒

-

2025-05-22 19:03:38

-

- 塞外医学明珠内蒙古医科大学

-

2025-05-22 19:01:24

-

- 千元机的新装备 高通骁龙450到底有多强?

-

2025-05-22 18:59:09

-

- 女人有外遇时,有以下几个特征

-

2025-05-22 18:56:55

-

- 处女座今日运势:爱情、事业、財富三丰收,幸运女神降临!

-

2025-05-22 18:54:41

-

- CSV德牧四川地方展 德牧届的选美大赛

-

2025-05-22 18:52:26

-

- 5月16日-9月14日郑尧高速郑州段19公里处施工辅道通行

-

2025-05-22 18:50:12

-

- 我国的外交官是什么级别?

-

2025-05-22 18:47:58

-

- 赖冠霖真名叫什么,赖冠霖与赵今麦什么关系为何取关她

-

2025-05-22 18:45:44

-

- 莱西市实验学校门前没有红绿灯?别急,规划来了,一起看看吧

-

2025-05-22 18:43:30

-

- 还记得那首火爆一时的够爱吗?它的2.0版陷入版权之争

-

2025-05-22 18:41:15

-

- 《陈情令》告别演唱会收官,肖战王一博“深情”对视,CP魂燃爆了

-

2025-05-22 18:39:01

-

- 新年钜礼丨历届维也纳新年音乐会珍藏版!

-

2025-05-22 18:36:47

-

- 通过合理设计,《方舟生存进化》木头房子一样能很豪华

-

2025-05-22 18:34:33

-

- 扫二维码抢红包 掉进骗子“陷阱”

-

2025-05-22 18:32:18

-

- 欧典娜智能集成扣板 打造时尚精美的家居环境

-

2025-05-22 18:30:04

-

- 何为人生常态

-

2025-05-22 18:27:50

-

- 《亚当斯一家的价值观》怪异与温馨并存经典哥特电影

-

2025-05-22 18:25:36

-

- 整新郎的招数创意点的方法

-

2025-05-22 18:23:21

-

- 1988年大授衔少将王申(原广州军区中将副司令员·湖北籍)

-

2025-05-21 22:27:23

一条烟不开封可以放多久?

一条烟不开封可以放多久? 彭冠英张含韵被曝结婚:低调的幸福爱情婚姻,或许与她的经历有关

彭冠英张含韵被曝结婚:低调的幸福爱情婚姻,或许与她的经历有关 王治郅的妻子周蕾,身材高挑 才貌双全 照片欣赏

王治郅的妻子周蕾,身材高挑 才貌双全 照片欣赏 范冰冰不雅图片 范爷大尺度裸身戏遭曝光

范冰冰不雅图片 范爷大尺度裸身戏遭曝光 扎西顿珠视为信仰的宗庸卓玛与平凡丈夫的爱情,七年卧床不离不弃

扎西顿珠视为信仰的宗庸卓玛与平凡丈夫的爱情,七年卧床不离不弃 中国著名相声演员姜昆简历

中国著名相声演员姜昆简历